DIGIT-BENCH (Digital Twin for Large-Scale Test Benches for the Wind Industry

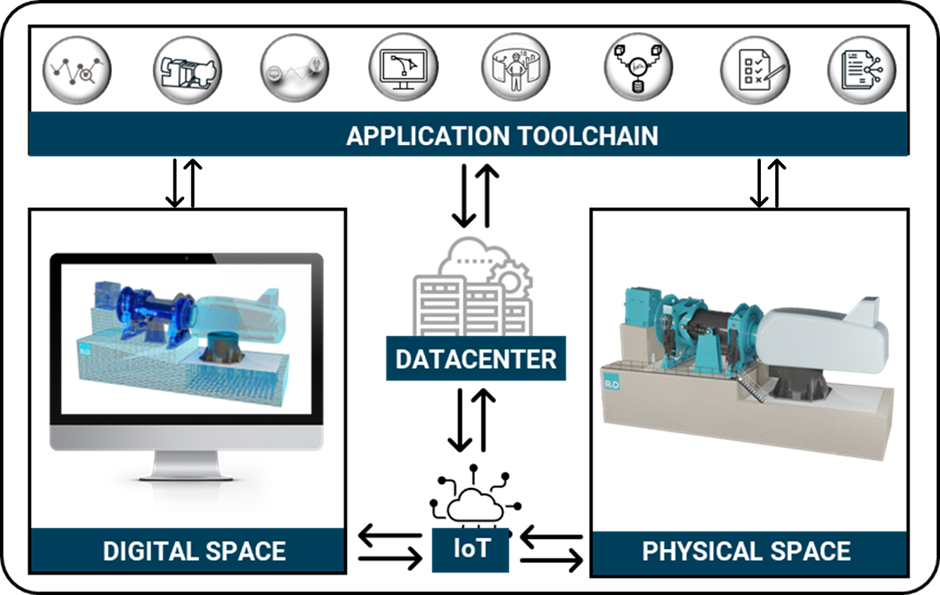

For wind turbine manufacturers and their sub-suppliers, testing is an essential part of ensuring the quality of both the design and manufacturing are of a high standard. However, to reduce the LCoE, wind turbine components keep getting bigger and bigger. This increase results in an ever-increasing cost of the test equipment and time needed for testing – resulting in an expensive and long time-to-market for new more efficient products. For example, the time required for executing the testing campaign for a new turbine blade can exceed 1 year. A substantial amount of time could be saved by optimizing operation of test benches and by replacing some of the physical testing with virtual testing. Digital Twin is the key-enabling technology to implement both actions. Building upon this scenario, DIGIT-BENCH aims to develop a Digital Twin framework for large-scale test benches serving in the wind industry. Specifically, Digital Twins are proposed for improving the operations and maintenance of the test benches as well as to support virtual testing. The project team is led by R&D Test Systems A/S, a world leader in delivering large-scale test benches for the wind industry, the Dept. of Civil and Architectural Engineering (AU-CAE), and the Dept. of Electrical and Computer Engineering of Aarhus University (AU-ECE), whose expertise is on Hybrid Testing and Digital Twin Technology. DIGIT-BENCH solution will be demonstrated at the Lindø Offshore Renewable Center (LORC), which is also partner of the project.